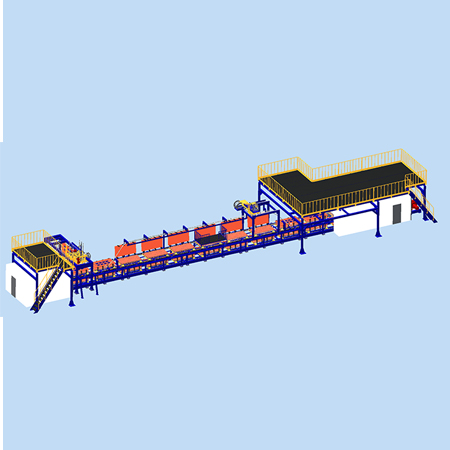

26 station drag chain type door foaming

2018/9/18

![]()

![]()

Product features

1 production process parameters:

1.1 curing time: 240 seconds ~390 sec.

1.2 Foaming agent type: cyclopentane + polyether + isocyanate foam or (cyclopentane + 245fa + polyether) + isocyanate foam

1.3 door body foaming type: integral foaming or split foaming (door shell under, inside lining).

1.4 injection type: closed manual injection and automatic injection molding.

1.5 beat: jig walking rhythm: 11S~16S adjustable.

2 main parameters of the fixture:

2.1 the structure of foam fixture: upper and lower double structure.

2.2 the template specification of the fixture is 2000mmX long 1000mmX and close height 150mm.

The number of 2.3 jobs is 26 stations.

2.4 maximum weight of mold: 500KG

3 technical description:

3.1 Adopt the two-layer caterpillar chain cyclic transmission structure, motor drive, frequency conversion speed regulation, drive the two-layer mold rack for cyclic movement, realize automatic mold opening, manual door shell, automatic injection (open mold, close mold two ways), automatic mold closing, curing cycle. It has high production efficiency and is suitable for multi variety production.

Z.N(zhongguo)Equipment and Mould manufacture Co.,Ltd 版权所有 皖ICP备18017416号-1 Disclaimer