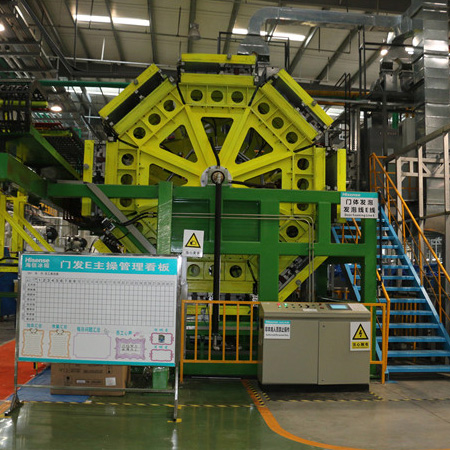

Double mixhead hydraulic rotation 8 station door foaming

2018/5/8

![]()

![]()

![]()

Product features

1 Overview

The equipment adopts hydraulic driving, rotating, opening and closing molds, connecting molds, double gun head servo driving and filling, clamp adopts mold temperature machine heating mode. At the same time, a pair of double-door refrigerator doors are produced to ensure the consistency of the left and right doors and meet the requirements of cyclopentane foaming.

2 production process parameters

2.1 curing time: 280 seconds to 400 seconds (any adjustable in 0--999 seconds):

2.2 type of blowing agent: (cyclopentane + polyether) + isocyanate.

2.3 door foaming form: split foaming (door shell under, inside lining).

2.4 injection form: open mold continuous charging;

2.5 mechanical beat (excluding manual time): no more than 45s

3 main parameters of equipment

3.1 size, length, width, height (approx.): 5.8m*7.8*5.2m

The number of 3.2 jobs is 8 stations.

3.3 fixture template specification (long X width): 2350mm*1200mm, mold width 1050mm (+0.5mm~+1mm);

3.4 closing height of template: 200mm;

3.5 maximum loading die weight: 800KG;

3.6 total power of equipment (approx.:90Kw);

Z.N(zhongguo)Equipment and Mould manufacture Co.,Ltd 版权所有 皖ICP备18017416号-1 Disclaimer